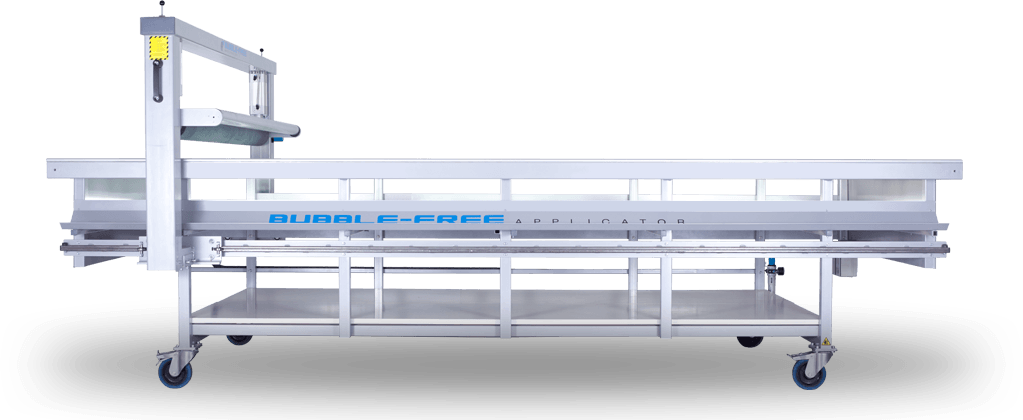

The Bubble-Free Applicator Table allows a single operator to mount and laminate a wide range of materials in superfast time whilst eliminating the danger of bubbles or creases.

-

Fast mounting & perfectly bubble and crease free

-

Increased production

-

Materials placed on top of each other won’t move

-

No more stretching inaccuracies

-

Simple and easy to learn

-

Also suitable for cutting tasks

Can be used for mounting and laminating onto any flat surface up to 60mm thick. The Bubble-Free applicator is available in two widths, 1500mm and 1700mm giving maximum working widths of 1420mm and 1640mm respectively. Rollers have 15mm of soft rubber thus ensuring bubble free application. The machine can be operated from either side giving greater installation flexibility.

WORKING SURFACE

MDF and glass working surface both ensure a good solution for cutting and applying layers on different materials with different thickness.

ROLL HOLDER

The roll holder gives you the opportunity to feed your material from a roll.

RUBBER ROLLER

The pressure roller has 15mm thick soft rubber coating, to guarantee the bubble free application. The roller presses the applied materials so they can’t move from their fixed position. The pressure of the roller can be adjusted over a wide range by the pneumatic controller.

SWITCH CONTROL

The pressure roller is controllable from both sides with a three-position switch which allows the height of the rubber roller to be adjusted. The maximum material thickness is 60 mm.

WHEELS WITH BRAKE

With the mounted wheels the table can be easily moved and fixed.

LED LIGHTING

The table is equipped with powerful but economical LED lighting. The LED provides an excellent and even light on the surface.

PNEUMATIC CONTROL UNIT

The pressure of the rubber roller should be set from 2.0 to 3.0 bar with the control unit. With 2 bar pressure you can even laminate perfectly on foam board without damaging it. For more sensitive materials the pressure should be tested before using it. The pneumatic system contains high quality HAFNER and FESTO parts

AIR TUBE PROTECTION

The cable channel and the hard plastic shell protects the air tubes from breaking and premature wear.

TECHNICAL DATA

| Model | 1500 | 1700 | 2200 |

|---|---|---|---|

| Working width | 1450mm | 1640mm | 2140mm |

| Table Width | 1500mm | 1700mm | 2200mm |

| Length of the table | 2800, 3400, 4000, 5400, 6000, 7000 mm | ||

| Working length | 2500, 3100, 3700, 5100, 5700, 6700 mm | ||

| Height of the table on wheels | 850mm | 850mm | 850mm |

| Max. material thickness | 60mm | 60mm | 60mm |

| Rubber roller diameter | 110 mm | 110 mm | 132 mm |

| Weight | 180, 270, 320, 480, 750, 840 kg | ||

| Warranty | 1 year | 1 year | 1 year |